-

Introducing our latest custom precision sheet metal parts: Elevate your prototyping experience

At HY Metals, we are committed to providing innovative solutions to meet the ever-changing needs of our customers. Our new custom precision sheet metal parts, including black powder-coated covers with rivet nuts and clear-anodized aluminum chassis components, exemplify our dedication to quality and precision.

If you’re looking for a reliable partner for your sheet metal prototyping needs, look no further than HY Metals. Contact us today to learn more about our capabilities and how we can help make your project a reality!

HY Metals provide one-stop custom manufacturing services including sheet metal fabrication and CNC machining, 14 years experiences and 8 fully owned facilities.

Excellent Quality control, short turnaround, great communication.

Send your RFQ with detailed drawings today. We will quote for you ASAP.

WeChat:na09260838

Tell:+86 15815874097

Email:susanx@hymetalproducts.com

-

Precision custom sheet metal electronic contactor parts

The first of these innovative products is a 6 mm diameter electronic contact component with a conductive claw ring. The precision bending required to form a closed circle at the end of this part is a testament to HY Metals’ advanced manufacturing capabilities. The part’s intricate design and small size present unique production challenges, but our team of skilled craftsmen and state-of-the-art machinery ensure that each piece meets the precise specifications listed in the drawing.

-

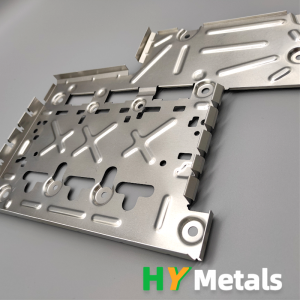

A Custom Sheet Metal Bracket Having Precision CNC Machining areas on several locations

HY Metals recently completed a project involving custom sheet metal parts made of Al5052 for automotive brackets.

After being laser cut, bent and riveted, the bracket required precision machining in four specific areas to create stepped circles. These stepped circles are necessary to accommodate the electronic components for the next stage of assembly. Despite the challenges of maintaining machining tolerances after bending, HY Metals successfully executed the project, ensuring a high-quality result.

-

Sheet Metal Prototyping: High precision sheet metal brackets aluminum bracket sheet metal parts

Aluminum Sheet Metal Brackets. Constructed from AL5052 aluminum and coated with a clear chromate film, these brackets reflect the company’s commitment to precision and surface protection. Even after multiple processes such as cutting, bending, chemical coating, riveting, etc., the bracket is still intact. HY Metals pays meticulous attention to every step of the production process to ensure that there are no scratches or damage.

-

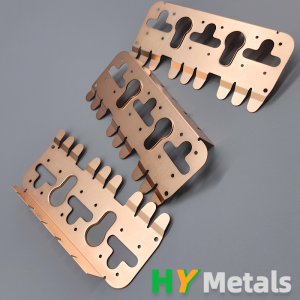

High precision sheet metal parts copper contactors sheet metal copper connectors

Part Name High precision sheet metal parts copper contactors sheet metal copper connectors Standard or Customized Customized Size 150*45*25mm,according to design drawings Tolerance +/- 0.1mm Material Copper, brass, beryllium copper, bronze, copper alloy Surface Finishes Sandblast, black anodizing Application Sheet metal prototype, electronics Process Laser cutting-Bending-welding-sandblasting-anodizing -

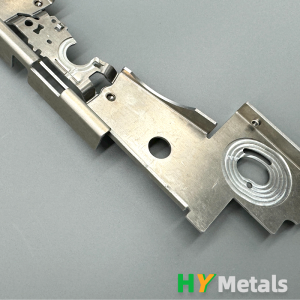

Custom Manufacturing service for Sheet Metal Prototype parts aluminum auto parts

Part Name High precision sheet metal prototype aluminum parts Standard or Customized Customized Size 275*217*10mm,according to design drawings Tolerance +/- 0.1mm Material Aluminum,AL5052,alloy Surface Finishes Clear anodizing Application Sheet metal prototype, auto parts Process Laser cutting-Forming-cutting -Bending -Anodizing -

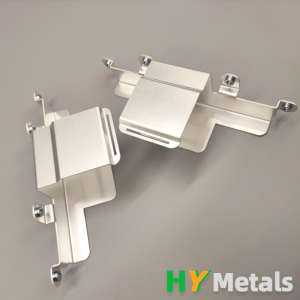

Custom galvanized steel sheet metal brackets for Electrical Boxes

Part Name Custom galvanized steel sheet metal brackets for Electrical Boxes Standard or Customized Customized Size 420*100*80mm,1.5mm thickness, according to design drawings Tolerance +/- 0.1mm Material Galvanized steel,SGCC,SECC Surface Finishes Galvanized Application Brackets for Electrical Boxes Process Laser cutting-Forming-Bending -Riveting -

Custom sheet metal welding and assembly

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together. Tapping and Riveting Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils. 1. Tapping threads Tapping is a process ... -

High-quality sheet metal welded component Custom aluminum welding assembly

Part Name High-quality sheet metal welded component Custom aluminum welding assembly Standard or Customized Customized Size 80*40*80mm,according to design drawings Tolerance +/- 0.1mm Material Aluminum tubes and aluminum sheet metal Surface Finishes Clear chromate, chemical film Application Sheet metal prototype, brackets Process Laser cutting-bending-Forming tubs- welding-chromate -

Precision Sheet metal bending and forming process

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Bending or Forming Sheet metal bending is the most important process in the sheet metal fabrication. It is a process of changing the material angle into a v-shaped or U-shaped, or other angles or shapes. The bending process makes the flat parts to be a formed part with angles, radius, flanges. Usually sheet metal bending includes 2 methods: Bending by Stamping Tooling and Bending by ben... -

OEM sheet metal parts with coating and silkscreen

Description Part Name Coated and silk-screened OEM sheet metal parts Standard or Customized Customized sheet metal parts and CNC machined parts Size According to drawings Tolerance According to your requirement, on demand Material Aluminum, steel, stainless steel, brass, copper Surface Finishes Powder coating, plating, anodizing,silkscreen Application For a wide range of industry Process CNC machining, sheet metal fabrication, coating, silkscreen Coated and silk-screened O... -

Sheet metal prototype with short turnaround

What is Sheet Metal Prototype? Sheet Metal Prototyping process is a rapid process producing simple or complex sheet metal parts without stamping tooling to save cost and time for prototype and low volume production projects. From the USB connectors, to computer cases, to manned space station, we can see sheet metal parts everywhere in our daily life, industry production and science technology application field. At the design and development stage, before mass production with the formal tool...