Professional China Rapid Prototyping - 3D printing service for rapid prototype parts – HY Metals

Professional China Rapid Prototyping - 3D printing service for rapid prototype parts – HY Metals Detail:

The Advantages of 3D printing?

● Very fast delivery,2-3 days possible

● Much more cheaper than traditional process.

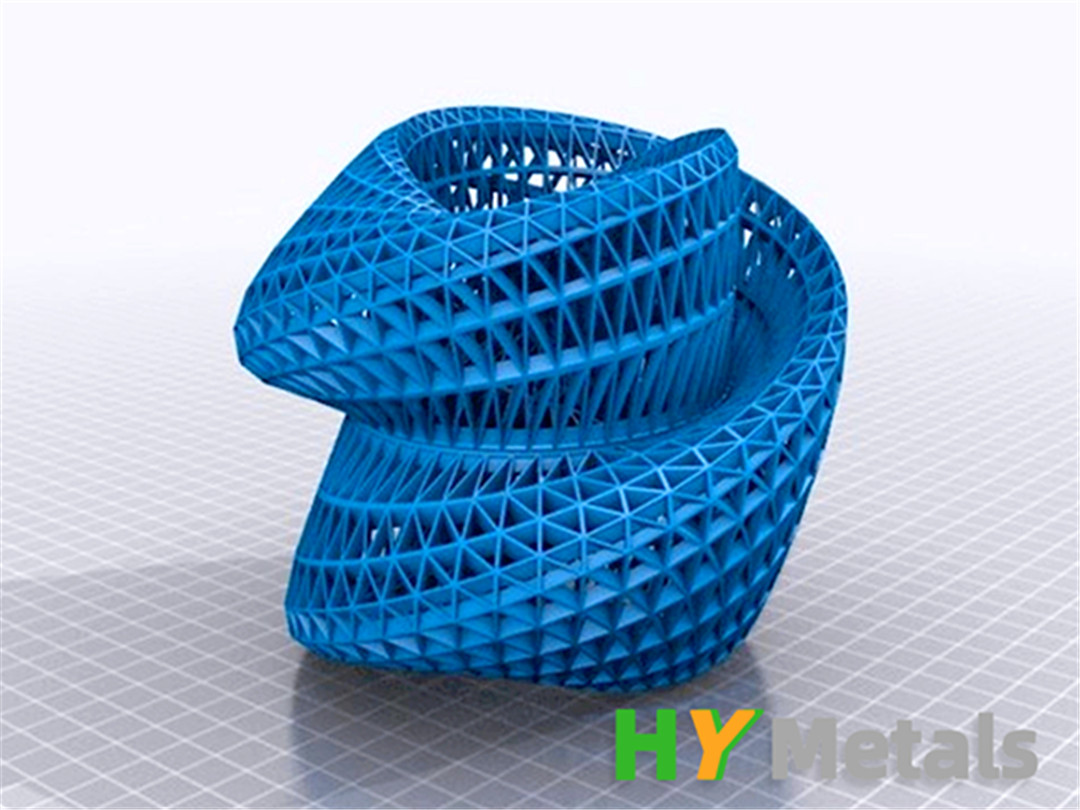

● 3D Printing technology break through the traditional manufacturing technology. Everything is possible to be printed.

● Overall printing, no assembly, save time and labors.

● Product diversification does not increase costs.

● Reduced reliance on artificial skills.

● Material infinite combination.

● There is no waste of tail material.

The common 3D printing techniques:

1. FDM: Melt deposition molding, the main material is ABS

2. SLA: Light curing rotten molding, the main material is photosensitive resin

3. DLP: Digital light processing molding, the main material is photosensitive resin

The forming principle of SLA and DLP technology is the same. SLA technology adopts laser polarization scanning irradiation point curing, and DLP adopts digital projection technology for layered curing. The accuracy and printing speed of DLP are better than SLA classification.

What types of 3D printing can HY Metals handle?

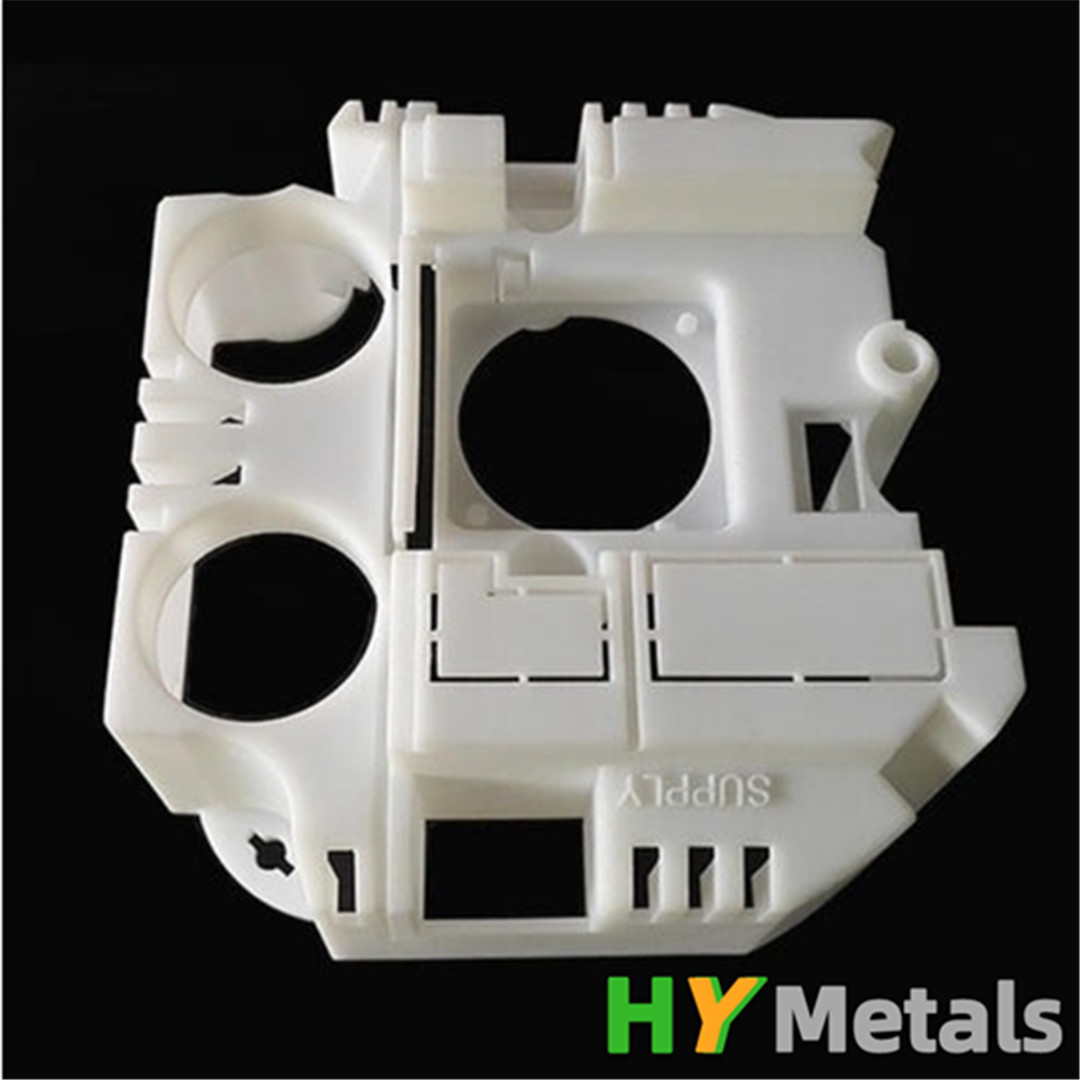

FDM and SLA are the most used in HY Metals.

And the most commonly used materials are ABS and photosensitive resin.

3D printing is much cheaper and faster than CNC machining or vaccum casting when the QTY is low like 1-10 sets, especially for complex structures.

However, it is limited by the printed material. We can only printed some plastic parts and very limit metal parts so for. And also, the surface of the printed parts are not as smooth as machining parts.

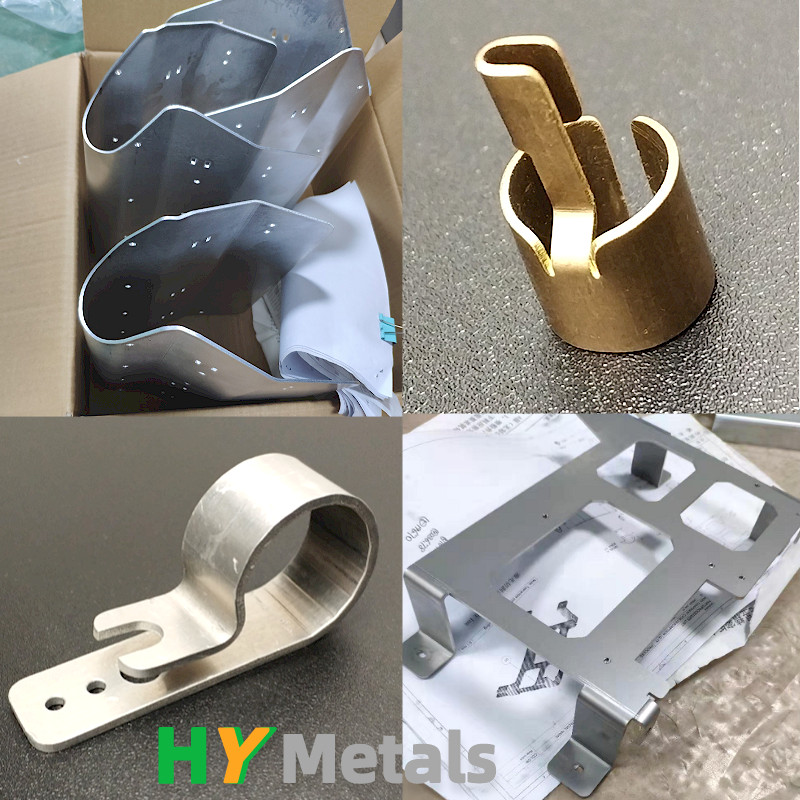

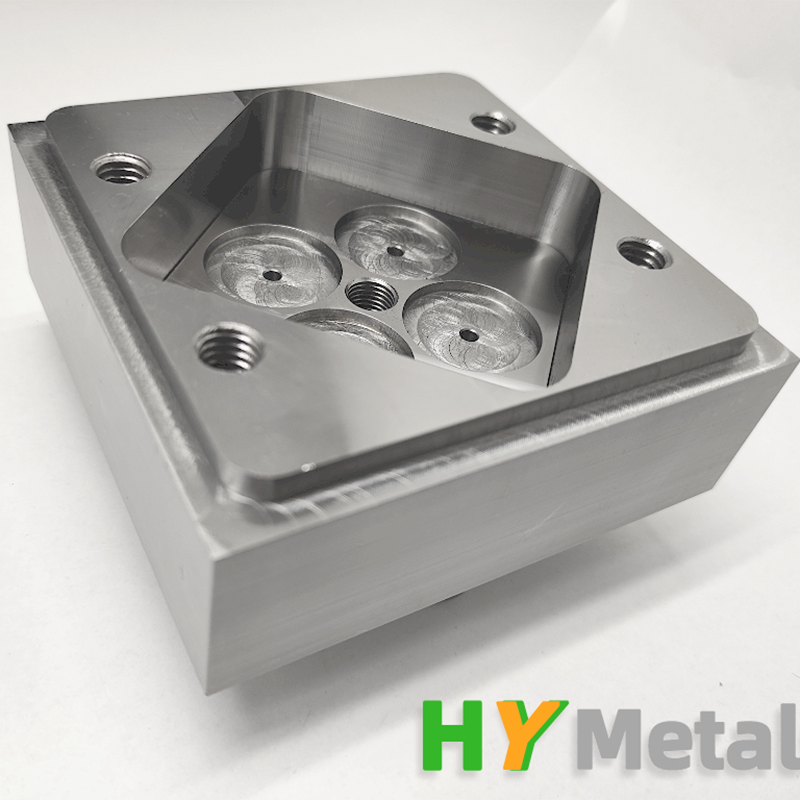

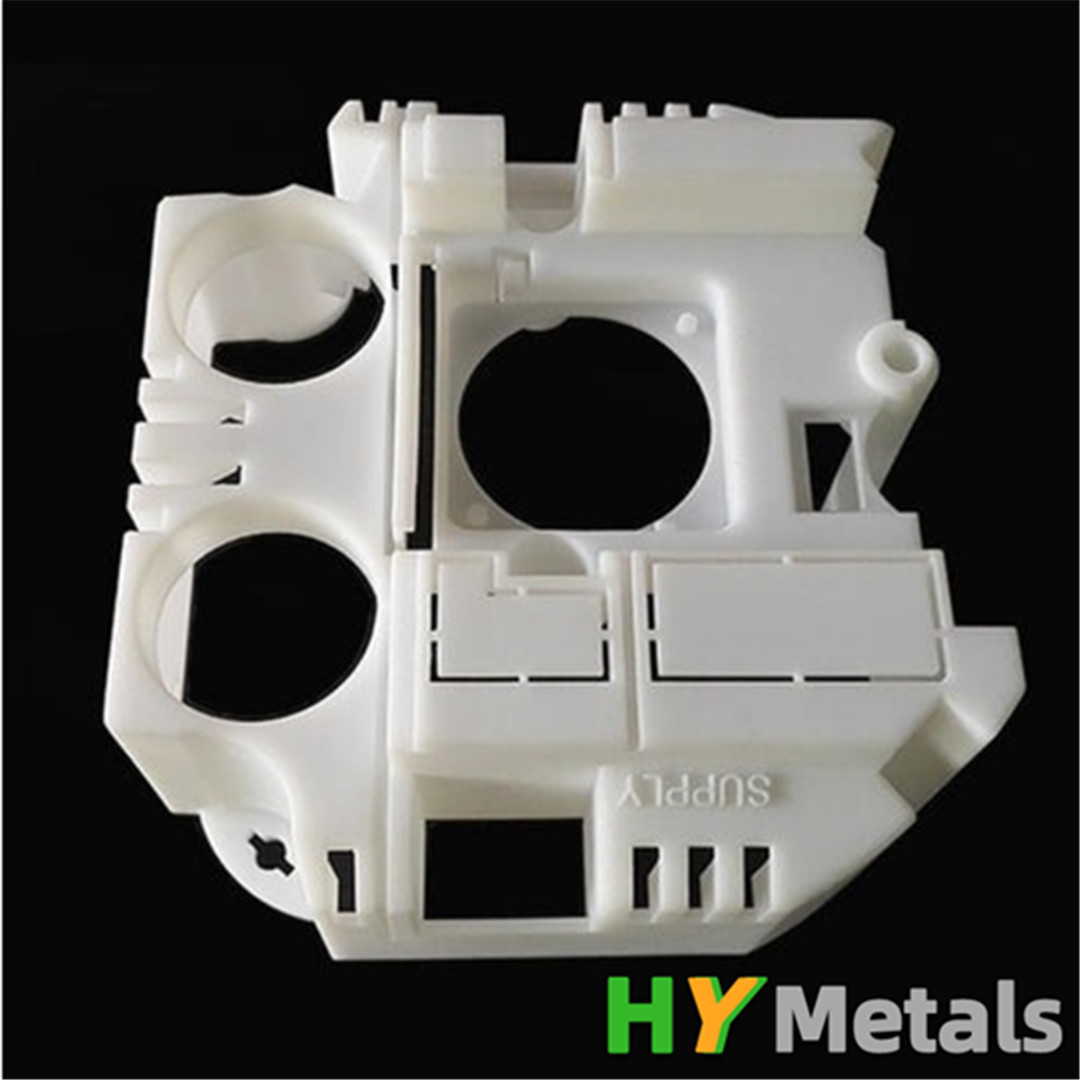

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Professional China Rapid Prototyping - 3D printing service for rapid prototype parts – HY Metals , The product will supply to all over the world, such as: Iran, Spain, US, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the client first principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!