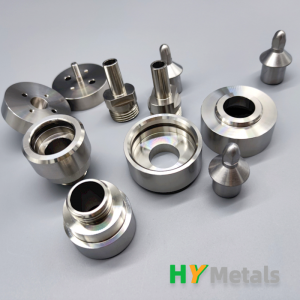

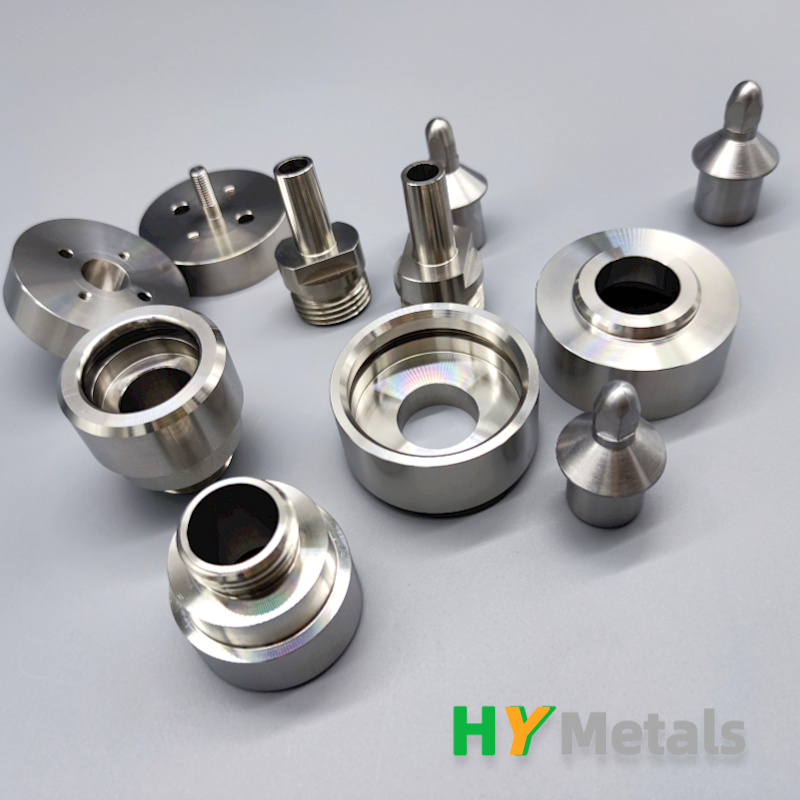

Precision machined Stainless Steel Parts: Defying Difficulties with HY Metals CNC Shop

Introduction:

As technology advances, the demand for CNC machined stainless steel parts with high quality, fine machined finish, and tight tolerance has increased significantly. Manufacturing companies rely on these precision components to enhance the performance and reliability of our products.

However, stainless steel is notoriously known for its challenging machinability due to its hardness and unique characteristics. This article will shed light on HY Metals CNC shop‘s expertise in manufacturing new stainless steel parts, highlighting our exceptional capabilities in milling and turning processes, achieving superior quality, and maintaining tight tolerances.

Machining Stainless Steel: A Challenging Art:

Working with stainless steel involves overcoming a series of complexities that can pose challenges for machining operations. Stainless steel’s hardness and heat resistance make it prone to excessive tool wear, deformation, and poor surface finish. Moreover, its high strength and low thermal conductivity require specialized approaches to minimize thermal distortion and ensure dimensional accuracy.

HY Metals CNC Shop: Mastering Stainless Steel Machining:

1.Equipment and Expertise:

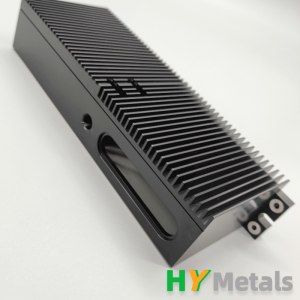

HY Metals CNC shop has state-of-the-art, computer numerical control (CNC) milling and turning machines specifically suited for stainless steel parts. Our experienced machinists possess the technical proficiency required to handle the intricate machining operations and delicate tooling necessary to work with stainless steel efficiently.

2.Material Selection:

Understanding the characteristics of different stainless steel grades is crucial. HY Metals CNC shop carefully selects the appropriate grade based on specific project requirements, such as corrosion resistance, strength, and machinability. This ensures optimal performance and enhances the longevity of the final product.

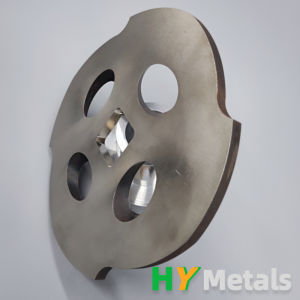

3.Precision Machining:

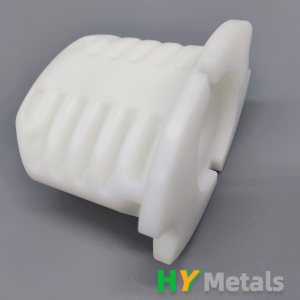

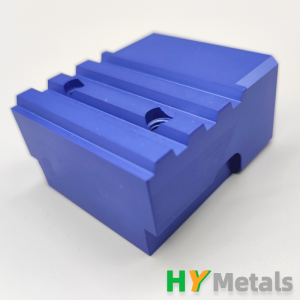

The shop employs advanced CNC milling and turning techniques to achieve precise dimensions and complex geometries. Computer-controlled processes allow for excellent repeatability, ensuring consistent quality across multiple parts. This precision machining also ensures tight tolerances, meeting or exceeding customer specifications.

4.Tool Selection and Optimization:

HY Metals CNC shop utilizes high-quality cutting tools designed specifically for machining stainless steel. These tools are engineered to withstand the demands of stainless steel machining, reducing tool wear, and minimizing machining errors. Additionally, the shop employs innovative tool path strategies, optimizing cutting conditions to enhance surface finish and accuracy.

5.Surface Finish and Quality:

HY Metals CNC shop places great emphasis on achieving an exceptional machined finish for stainless steel parts. Utilizing various techniques, such as precision grinding, polishing, and electropolishing, they ensure smooth surfaces, removing any imperfections and providing a visually appealing appearance. This attention to detail enhances the durability and aesthetics of the final stainless steel components.

6.Quality Assurance:

To guarantee the highest quality standards, HY Metals CNC shop employs rigorous quality control measures. They have an in-house inspection team that uses advanced metrology equipment, including coordinate measuring machines (CMMs), to verify part dimensions, tolerances, and surface finish. This ensures that every stainless steel part leaving our facility meets or exceeds customer expectations.

Conclusion:

Through our expertise in CNC milling and turning, HY Metals CNC shop has mastered the art of machining stainless steel parts with high precision, fine machined finish, and tight tolerances. Despite the challenges posed by stainless steel, our advanced equipment, material knowledge, and skilled workforce allow us to overcome these difficulties efficiently. By utilizing state-of-the-art techniques and maintaining strict quality control measures, HY Metals has established itself as a trusted manufacturer of superior stainless steel components.