For Sheet metal parts, adding stiffeners is critical to ensuring their strength and durability. But what are ribs, and why are they so important to sheet metal parts? Also, how do we make the ribs during the prototyping stage without using stamping tools?

First, let’s define what a rib is. Essentially, a rib is a flat, protruding structure added to a sheet metal part, usually on its bottom or inside surface. These structures provide extra strength and robustness to the part, while also preventing unwanted deformation or warping. By adding ribs, sheet metal parts can withstand greater loads and pressures, making them more reliable and durable.

So, why do we need to add ribs to sheet metal parts? The answer lies in the complexity of these parts. Sheet metal parts are often subjected to a variety of forces, including bending, twisting, and stamping. Without adequate reinforcement, these components can quickly succumb to this force, causing failure or breakage. Ribs provide the necessary support and reinforcement to prevent such problems from occurring.

Now, let’s move to the prototyping stage. In the early stages of development, it is critical to create and test various versions of sheet metal parts before series production. This process requires accuracy, precision and speed. Typically, creating ribs during prototyping requires the use of stamping tools, which can be expensive and time-consuming. However, there is another way to make ribs during the prototyping stage – with simple tools.

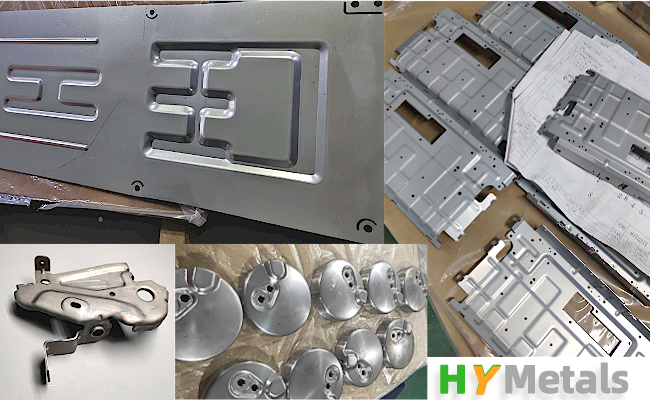

At HY Metals, we specialize in precision sheet metal fabrication, including the manufacture of thousands of ribbed automotive sheet metal parts. During the prototyping phase, we made the ribs using simple tools and matched the drawings. We carefully prototype sheet metal parts and ensure that stiffeners provide the necessary strength and reinforcement required. By using simple tools during the prototyping stage to create ribbed sheet metal parts, we can reduce the time and cost required for stamping tooling.

In summary, adding stiffeners to sheet metal parts is critical to increasing their strength and durability. The complexity of sheet metal parts requires adequate reinforcement to prevent unwanted deformation or warping. During the prototyping phase, various versions of sheet metal parts must be created and tested while saving as much time and cost as possible. HY Metals has the experience and expertise to manufacture ribbed sheet metal parts without the use of expensive stamping tools. By using simple tools, we can meet the precise requirements of each sheet metal part while saving our customers time and money.

Post time: Mar-25-2023