The work experience and technical level of bending technical workers have a significant impact on the sheet metal bending process. Here are some of the key areas where their expertise plays a key role:

1.Tooling Selection: Experienced bending technical workers can effectively select appropriate tooling based on material type, thickness, and bending requirements. Their knowledge allows them to select the correct die and punch combination to achieve the desired bend angle and radius.

2. Machine Setup and Calibration: A skilled worker can skillfully set up and calibrate a press brake, ensuring that it is configured to accurately bend sheet metal according to specified parameters. This includes adjusting the back gauge, aligning the tool, and entering the correct bending program.

3. Bend Allowance Calculation: A deep understanding of material behavior and the ability to accurately calculate bend allowances is critical. Experienced workers can anticipate and compensate for material spring back to achieve precise final dimensions after bending.

4. Quality Control: Technical bending workers with professional knowledge can effectively inspect the bent parts to ensure that the dimensions, angles and overall quality meet the required specifications. Their ability to identify and resolve any deviations or defects is critical to maintaining high quality production.

5. Problem Solving and Optimization: Experienced workers can solve problems that may arise during the bending process, such as material deformation, mold wear, or inconsistent bending results. Their ability to optimize processes and adjust dynamically contributes to efficient, reliable production.

6. Safety and Efficiency: Skilled workers are well versed in safety protocols and best practices for operating bending machinery. Their expertise helps create a safe work environment and efficient use of equipment.

To sum up, the work experience and technical proficiency of bending technical workers have a great impact on the quality, efficiency and safety of sheet metal bending processing. Their expertise in tool selection, machine setup, bend allowance calculations, quality control, problem solving and safety practices are critical to achieving consistent and accurate bending results.

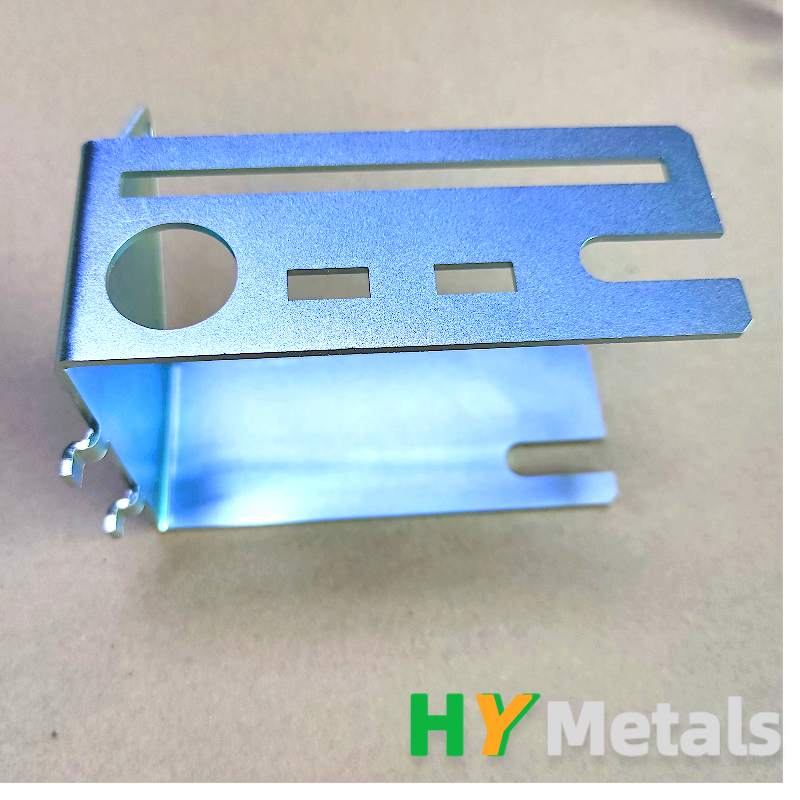

HY Metals has a excellent sheet metal bending team,all the bending workers have over 5 -15years experience.

HY Metals provide one-stop custom manufacturing services including sheet metal fabrication and CNC machining, 14 years experiences and 8 fully owned facilities.

Excellent Quality control,short turnaround,great communication.

Send your RFQ with detailed drawings today.We will quote for you ASAP.

WeChat: na09260838

Tell: +86 15815874097

Email: susanx@hymetalproducts.com

Post time: Jul-19-2024