Introduce:

Sheet metal fabrication is an important aspect of custom manufacturing, and one of the key processes involved is welding and assembly. With its extensive experience and cutting-edge capabilities in sheet metal fabrication, HY Metals is constantly striving to enhance its welding techniques to deliver superior results. In this blog post, we explore the importance of welding and assembly in precision sheet metal fabrication, and how HY Metals is raising the bar with its recent investment in new welding machines.

The importance of welding and assembly:

Welding and assembly play a vital role in sheet metal fabrication as they ensure the structural integrity and functionality of the final product. Whether joining multiple parts together or creating complex assemblies, precision welding is key to achieving desired results. Welding not only provides strength and durability, but also ensures that the final product meets the required specifications.

HY Metals Commitment to Quality:

With four sheet metal factories and four CNC machining shops, HY Metals has become a leader in the industry. Their 13 years of experience, extensive machinery and a team of 350 highly trained employees make them the go-to solution for your sheet metal fabrication needs. HY Metals’ commitment to quality is reflected in their continuous efforts to improve welding and assembly processes.

New welding machine investment:

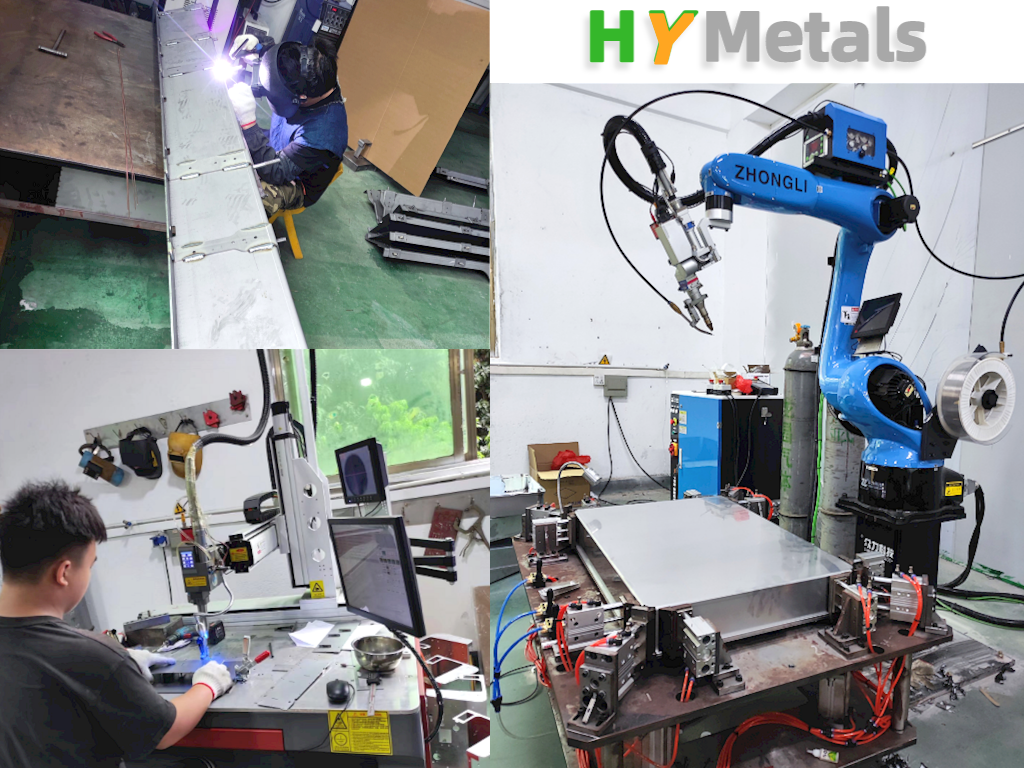

To further enhance its capabilities, HY Metals recently purchased new welding machines. These include welding robots and automated welding machines that significantly increase welding speed and precision. These machines ensure that welding is performed with the highest precision and efficiency, resulting in beautiful and structurally sound sheet metal products.

Advantages of the new welding machine:

The introduction of welding robots and automated welding machines revolutionized the welding process at HY Metals. These machines have higher precision and speed, which can speed up production and increase productivity. Automated welding machines eliminate the risk of human error, while welding robots can perform complex welding tasks with impeccable precision. These advances in welding technology have enabled HY Metals to provide customers with products of superior quality – both in appearance and function.

HY Metal’s Expertise:

As well as state-of-the-art welding machines, HY Metals prides itself on the expertise of its welders and the high precision of its machines. Skilled professionals and state-of-the-art equipment combine to ensure that every welding job is executed to perfection. HY Metals differentiates itself from the competition by focusing on hiring and training knowledgeable welders and investing in quality machinery.

In summary:

Welding and assembly are key processes in sheet metal fabrication and HY Metals recognizes their importance. By investing in new welding equipment, including welding robots and automated welding machines, HY Metals has achieved significant improvements in welding speed, precision and overall quality. With extensive experience, strong capabilities and a commitment to perfection, HY Metals continues to impress clients with its exceptional sheet metal fabrication services.

Post time: Jul-21-2023