Powder coating is a method of surface preparation that involves applying a powder coating to a metal surface, which is then cured under heat to form a hard, durable finish. Metal sheet is a popular powder coating material due to its strength, flexibility and versatility.

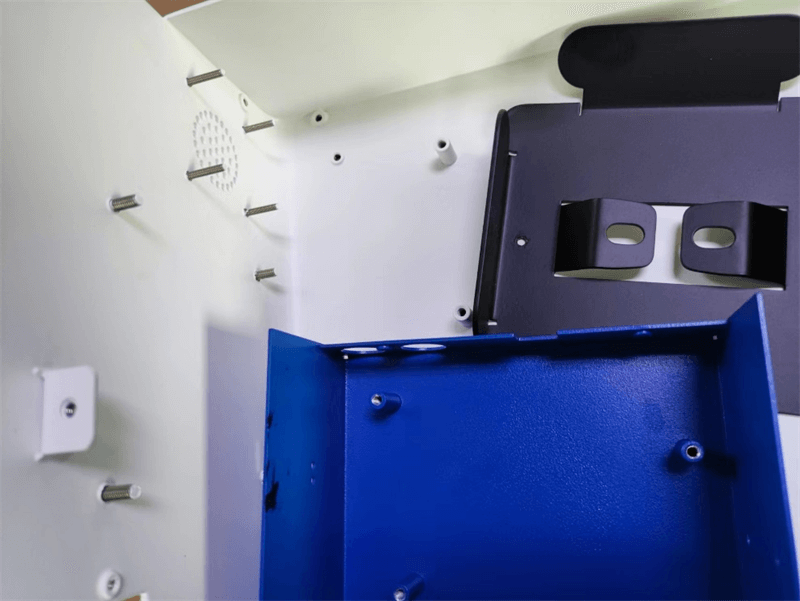

Especially for some sheet metal bracket, sheet metal case, sheet metal cover and bottom, sheet metal parts that need a better surface and good corrosion resistance.

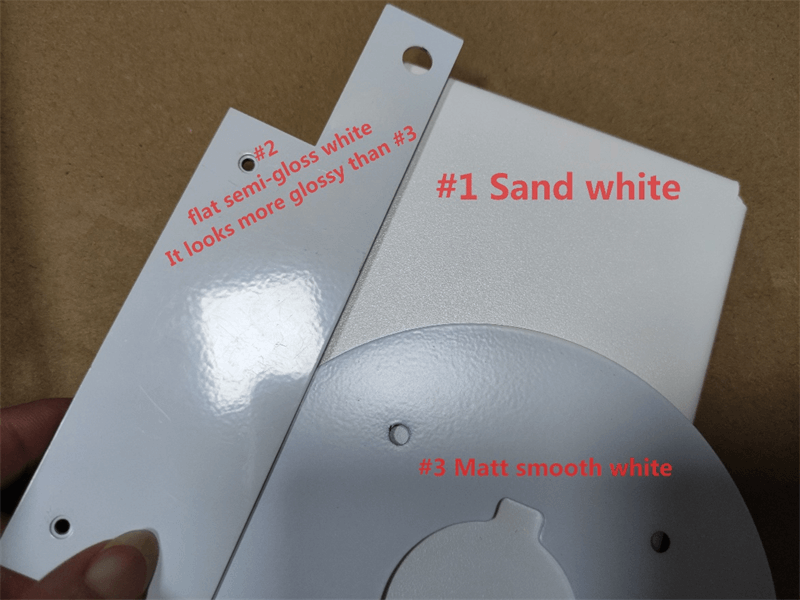

You can custom all kinds of colors and textures you like for your powder coating finish in HY metals. We usually match colors according to your color samples or RAL color number and Panton color number.

And even a same color number we can match different texture finish effect.

For example the below 2 pictures show different effect for black and white color.

There is semi-gloss black, sand black and smooth matte black.

There are many benefits to applying a powder coat finish to sheet metal parts, including improved corrosion resistance, durability, and aesthetics. Powder coatings are an environmentally friendly alternative to traditional liquid coatings because they emit lower levels of volatile organic compounds (VOCs) and generate less waste.

One of the significant advantages of powder coating of sheet metal is the ability to provide a uniform and consistent finish even on complex surface areas. Powder coatings can be applied in various thicknesses depending on the requirements of the metal part. If the sheet metal part will be used in a harsh environment, a thicker coating can be applied to provide additional corrosion and wear protection.

Another significant advantage of powder coating sheet metal parts is its ability to withstand extreme temperatures, making it ideal for parts such as engine parts or industrial machinery that will be exposed to high temperatures. The powder coat finish also resists fading, chalking and peeling, ensuring a long-lasting, beautiful finish.

Powder coating of sheet metal parts is used in a variety of industries including automotive, aerospace, construction and manufacturing. Powder coating finishes are available in a variety of colors and textures, allowing manufacturers to choose the right finish for their branding or design needs.

The application of powder coating to sheet metal parts can reduce maintenance costs because it requires little maintenance and the coated parts are easy to clean. The powder-coated smooth surface finish resists dirt and grime build-up, making it easy to clean with mild soap and water or a pressure washer.

Powder coating in sheet metal parts is also suitable for use in the medical and food processing industries as it resists bacterial growth and can be easily sterilized. A powder-coated finish has a smooth finish with no crevices or pores where bacteria could harbor, making it an ideal surface for tools, equipment and medical devices.

In summary, applying a powder coat finish to sheet metal parts offers a range of benefits, including improved corrosion resistance, durability and aesthetics. Powder coatings are an environmentally friendly alternative to traditional liquid coatings and are used in a wide variety of industries. Its ability to withstand extreme temperatures and reduce maintenance costs makes it ideal for automotive, aerospace, construction and manufacturing applications. Powder coatings are also suitable for use in the medical and food processing industries due to their resistance to bacterial growth and surface finish that can be easily sanitized.

Post time: Mar-16-2023