-

Good Quality Sheet Metal Prototype - Sheet metal prototype with short turnaround – HY Metals

What is Sheet Metal Prototype? Sheet Metal Prototyping process is a rapid process producing simple or complex sheet metal parts without stamping tooling to save cost and time for prototype and low volume production projects. From the USB connectors, to computer cases, to manned space station, we can see sheet metal parts everywhere in our daily life, industry production and science technology application field. At the design and development stage, before mass production with the formal tool... -

Good quality Sheet Metal Components - Custom sheet metal welding and assembly – HY Metals

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together. Tapping and Riveting Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils. 1. Tapping threads Tapping is a process m... -

OEM/ODM China Sheet Metal Cover - Custom sheet metal welding and assembly – HY Metals

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Sheet metal assembly is the process after cutting and bending, sometimes it is after coating process. We usually assemble parts by riveting, welding, pressing fit and tapping to screw them together. Tapping and Riveting Threads are playing an important role in assemblies. There are 3 main methods to get threads: Tapping, riveting, install coils. 1. Tapping threads Tapping is a process m... -

Manufacturing Companies for Small Turned Parts - Materials and finishes for sheet metal parts and CNC machined parts – HY Metals

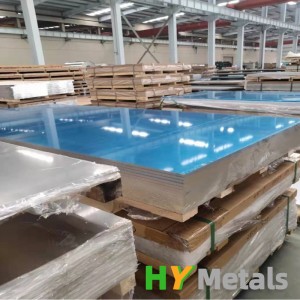

HY metals is your best supplier of custom sheet metal parts and machining parts with more than 10 years of experience and ISO9001:2015 cert. We own 6 fully equipped factories including 4 sheet metal shops and 2 CNC machining shops. We provide professional custom metal and plastic prototyping and manufacturing solutions. HY Metals is a grouped company providing one-stop service from raw materials to end use products. We can handle all kinds of materials including Carbon Steel, Stainless steel,... -

Factory Supply Sheet Metal Box Fabrication - Precision Sheet metal bending and forming process – HY Metals

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. Bending or Forming Sheet metal bending is the most important process in the sheet metal fabrication. It is a process of changing the material angle into a v-shaped or U-shaped, or other angles or shapes. The bending process makes the flat parts to be a formed part with angles, radius, flanges. Usually sheet metal bending includes 2 methods: Bending by Stamping Tooling and Bending by ben... -

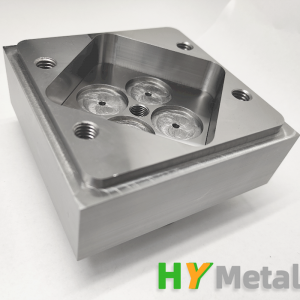

Good Quality CNC Machining - Precision CNC machining service including milling and turning with 3 axis and 5 axis machines – HY Metals

CNC Machining For many metal parts and engineering grade plastic parts, CNC precision machining is the most commonly used production method. It is also very flexible for prototype parts and low-volume production. CNC machining can maximize the original characteristics of engineering materials including strength and hardness. CNC Machined parts are ubiquitous on industrial automation and mechanical equipment parts. You can see machined bearings, machined arms, machined brackets, machined cover... -

Good quality Sheet Metal Components - Precision metal cutting processes including Laser cutting, Chemical etching and Water Jet – HY Metals

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. The sheet metal materials are usually some metal plates with the size of 1220*2440mm, or metal rolls with a specified width. So according to different custom metal parts, first step will be cut the material to the suited size or cut the whole plate according to the flat pattern. There are 4 main types of cutting methods for sheet metal parts: Laser cutting, water jet, Chemical etching, s... -

100% Original Cnc Machining Precision Parts - Sheet metal prototype with short turnaround – HY Metals

What is Sheet Metal Prototype? Sheet Metal Prototyping process is a rapid process producing simple or complex sheet metal parts without stamping tooling to save cost and time for prototype and low volume production projects. From the USB connectors, to computer cases, to manned space station, we can see sheet metal parts everywhere in our daily life, industry production and science technology application field. At the design and development stage, before mass production with the formal tool... -

Lowest Price for U Shaped Sheet Metal - Precision metal cutting processes including Laser cutting, Chemical etching and Water Jet – HY Metals

Sheet Metal Fabrication Processes: Cutting, Bending or Forming, Tapping or Riveting, Welding and Assembly. The sheet metal materials are usually some metal plates with the size of 1220*2440mm, or metal rolls with a specified width. So according to different custom metal parts, first step will be cut the material to the suited size or cut the whole plate according to the flat pattern. There are 4 main types of cutting methods for sheet metal parts: Laser cutting, water jet, Chemical etching, s... -

High Quality Milling Parts - Materials and finishes for sheet metal parts and CNC machined parts – HY Metals

HY metals is your best supplier of custom sheet metal parts and machining parts with more than 10 years of experience and ISO9001:2015 cert. We own 6 fully equipped factories including 4 sheet metal shops and 2 CNC machining shops. We provide professional custom metal and plastic prototyping and manufacturing solutions. HY Metals is a grouped company providing one-stop service from raw materials to end use products. We can handle all kinds of materials including Carbon Steel, Stainless steel,... -

China wholesale CNC Machined Parts - Sheet metal prototype with short turnaround – HY Metals

What is Sheet Metal Prototype? Sheet Metal Prototyping process is a rapid process producing simple or complex sheet metal parts without stamping tooling to save cost and time for prototype and low volume production projects. From the USB connectors, to computer cases, to manned space station, we can see sheet metal parts everywhere in our daily life, industry production and science technology application field. At the design and development stage, before mass production with the formal tool... -

High reputation Robot Arm Cnc Milling - Sheet metal prototype with short turnaround – HY Metals

What is Sheet Metal Prototype? Sheet Metal Prototyping process is a rapid process producing simple or complex sheet metal parts without stamping tooling to save cost and time for prototype and low volume production projects. From the USB connectors, to computer cases, to manned space station, we can see sheet metal parts everywhere in our daily life, industry production and science technology application field. At the design and development stage, before mass production with the formal tool...