Exploring the world of 3D printed prototypes: achieving high quality with HY Metal

Welcome to HY Metals’ web, where we provide you with insights into the exciting world of custom manufacturing.

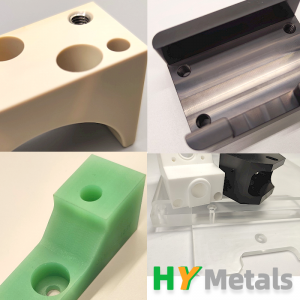

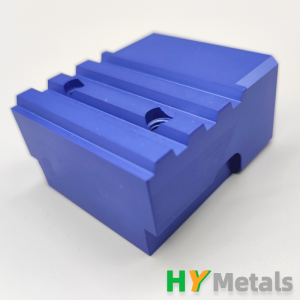

Our one-stop services include sheet metal fabrication, CNC machining, 3D printing and vacuum casting, all designed to deliver high-precision rapid prototyping with short turnaround times. In this article, we will highlight the features and benefits of 3D printed prototypes, focusing on printed ABS parts.

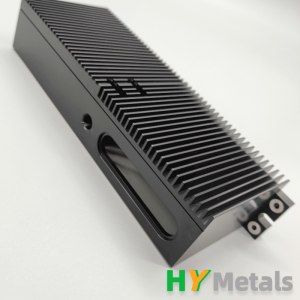

When it comes to rapid prototyping, time and cost are crucial factors. Traditional manufacturing processes such as CNC machining or vacuum casting are time-consuming and expensive, especially when the required quantities are low (1 to 10 sets). This is where 3D printing becomes a more advantageous solution, offering a faster and more affordable alternative, especially for complex structures.

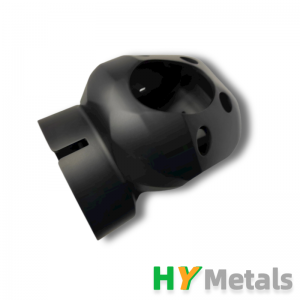

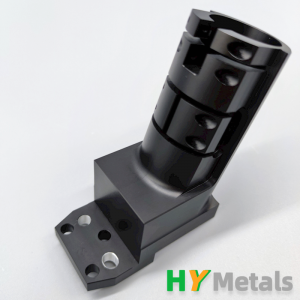

At HY Metals we understand the importance of aesthetics. After the 3D printing process, our team carefully painted the ABS parts black, enhancing the overall appearance and ensuring a seamless finish. This extra step transforms the printed parts, making them visually appealing and beautiful. Whether you need prototypes for design evaluation or marketing purposes, our printed ABS parts will impress both visually and functionally.

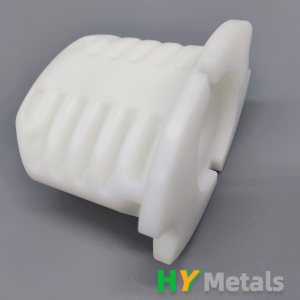

However, it’s worth noting that 3D printing does have its limitations. Printing material options are mainly limited to plastics, with limited use of metal parts currently. While we continue to explore ways to expand our range of printing materials, plastic parts remain the primary focus of our 3D printing services. Despite this limitation, the advantages of 3D printing in terms of cost, speed, and complexity make it an attractive option for numerous applications.

While the surface of 3D printed parts may not be as smooth as parts produced through traditional machining processes, the innovative nature of 3D printing makes up for this shortcoming. Rapid prototyping is an effective tool for design verification and validation, enabling designers and engineers to detect and correct errors early in the development phase. This helps reduce the time and costs associated with rework and improves overall product quality.

At HY Metals, we pride ourselves on delivering exceptional quality and precision to our customers. Our dedicated team of experts ensures that every product, including 3D printed ABS parts, meets the highest standards of excellence. We believe that by combining our expertise in sheet metal fabrication, CNC machining and vacuum casting with the versatility of 3D printing, we can provide you with comprehensive solutions tailored to your specific needs.

In summary, 3D printed prototypes offer a cost-effective and time-saving option, especially for low quantity requirements and complex structures. While there may be limitations in material selection and surface finish, HY Metals ensures that our 3D printed ABS parts receive the utmost attention to detail, turning them into visually stunning functional prototypes. Trust us to be your innovative and precise partner, providing you with the highest quality results that exceed your expectations.